+86 17737144966

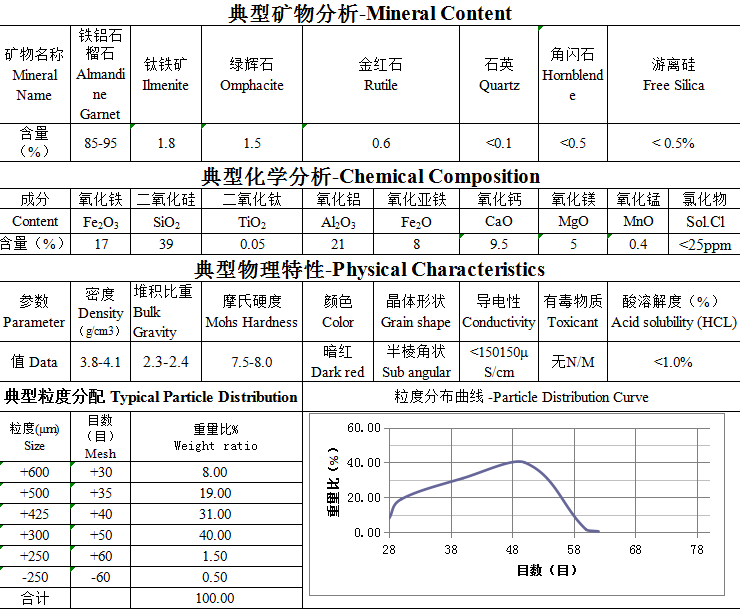

Garnet, with the chemical formula A3B2(SiO4)3, is a common silicate mineral. Its main components include calcium, magnesium, iron, aluminum and other elements. Garnet has a high hardness of 6.5-7.5, a hard texture, wear resistance and corrosion resistance, and is an ideal natural abrasive.

Garnet is a natural silicate mineral, and its main components are aluminum oxide, silicon oxide and iron oxide. Garnet has the characteristics of high hardness, good wear resistance and strong chemical stability, so it is widely used in the industrial field. Garnet has various colors, the common ones are red, yellow, green, etc., and its particle size can be screened according to needs.

Chemical composition: The main component of garnet is silicate, and its chemical formula is A3B2(SiO4)3, where A is metal ions such as calcium, magnesium, and iron, and B is metal ions such as aluminum, manganese, and chromium.

Physical properties: The density of garnet is 3.5-4.3g/cm³, the hardness is 6.5-7.5, the compressive strength is 200-300MPa, the melting point is 1300-1650℃, and it has good high temperature resistance.

Electrical properties: The conductivity of garnet is low, generally in the range of 10^-6 - 10^-8 S/cm, and it has good insulation properties.

Efficient rust removal: Garnet has good grinding performance and can effectively remove rust, layers, grease and other dirt on the metal surface. Compared with traditional rust removal methods such as sandpaper and wire brushes, garnet sandblasting rust removal is faster and more effective.

Green and environmentally friendly: Garnet is a natural mineral, pollution-free and non-toxic. During the sandblasting rust removal process, no harmful gases and dust are generated, which is beneficial to protecting the environment and human health.

High durability: Garnet has high hardness, good wear resistance and long service life. During the sandblasting rust removal process, the consumption rate of garnet abrasive is relatively slow, which reduces production costs.

Wide range of application: Garnet abrasive is suitable for surface treatment of various metals, concrete and other materials, such as ships, bridges, pipelines, storage tanks, etc.

Sandblasting equipment: Sandblasting equipment using garnet as abrasive mainly includes sandblasting guns, sandblasting tanks, air compressors, etc. During the sandblasting process, garnet abrasive is placed in the sandblasting tank, and the abrasive is sprayed onto the surface of the object to be rusted through the air compressor.

Sandblasting process: Sandblasting and rust removal processes mainly include dry sandblasting and wet sandblasting. Dry sandblasting is to spray garnet abrasive directly onto the surface of the object, which is suitable for rust removal of most metal materials; wet sandblasting is to spray garnet abrasive after mixing it with water, which is suitable for metal materials with high surface quality requirements.

Sandblasting rust removal uses high-pressure gas to spray abrasives onto the metal surface to achieve the purpose of rust removal, decontamination, polishing, etc. Garnet has the following advantages as an abrasive in sandblasting rust removal:

Low conductivity: Garnet has a low conductivity, which can effectively prevent the damage of electric current to the metal surface and ensure the integrity of the metal surface.

High hardness: Garnet has a high hardness and can effectively remove rust and oxide layers on the metal surface, improving the finish of the metal surface.

Good wear resistance: Garnet has good wear resistance and long service life, reducing the cost of sandblasting rust removal.

Strong chemical stability: Garnet will not react chemically with the metal surface during sandblasting rust removal, ensuring the quality of the metal surface.

Key points of operation: During the sandblasting process, operators should pay attention to the following points:

(1) Ensure that the sandblasting equipment is working properly and the pressure is stable;

(2) Select the appropriate garnet abrasive particle size to achieve the ideal rust removal effect;

(3) Control the sandblasting speed to avoid being too fast or too slow to avoid affecting the rust removal effect;

(4) Maintain the sandblasting distance, generally 150-300mm, to obtain a uniform rust removal effect;

(5) Pay attention to the moving speed of the sandblasting gun to avoid staying in the same position for too long and over-grinding locally.

25kg/bag or 1000kgs/jumbo bag

20GP FCL :25-27TONS

40GP FCL: 25-28TONS

40HQ FCL:25 TONS or 28 TONS

The above quantity without pallet ,the goods will be sent within 7-15days after receiving your order.

Zhengzhou Jiasheng Water Purification Materials Co., Ltd. is a manufacturer specializing in the production of garnet. The company adopts advanced production technology and equipment, strictly controls product quality, and provides customers with high-quality sandblasting rust removal garnet. The following are the characteristics of the company's garnet products:

Uniform particle size: The garnet particles are uniform in size, which is conducive to the improvement of sandblasting rust removal effect.

Moderate hardness: Garnet has moderate hardness, which can effectively remove rust on the metal surface without causing damage to the metal surface.

Good wear resistance: Garnet has good wear resistance, long service life, and reduces the cost of sandblasting rust removal.

Strong chemical stability: Garnet does not react chemically with the metal surface during sandblasting rust removal, ensuring the quality of the metal surface.

Reasonable price: The company's products are reasonably priced, cost-effective, and well received by customers.

In short, garnet has significant advantages in the field of sandblasting rust removal. Zhengzhou Jiasheng Water Purification Materials Co., Ltd. supplies high-quality garnets. Welcome to contact us.